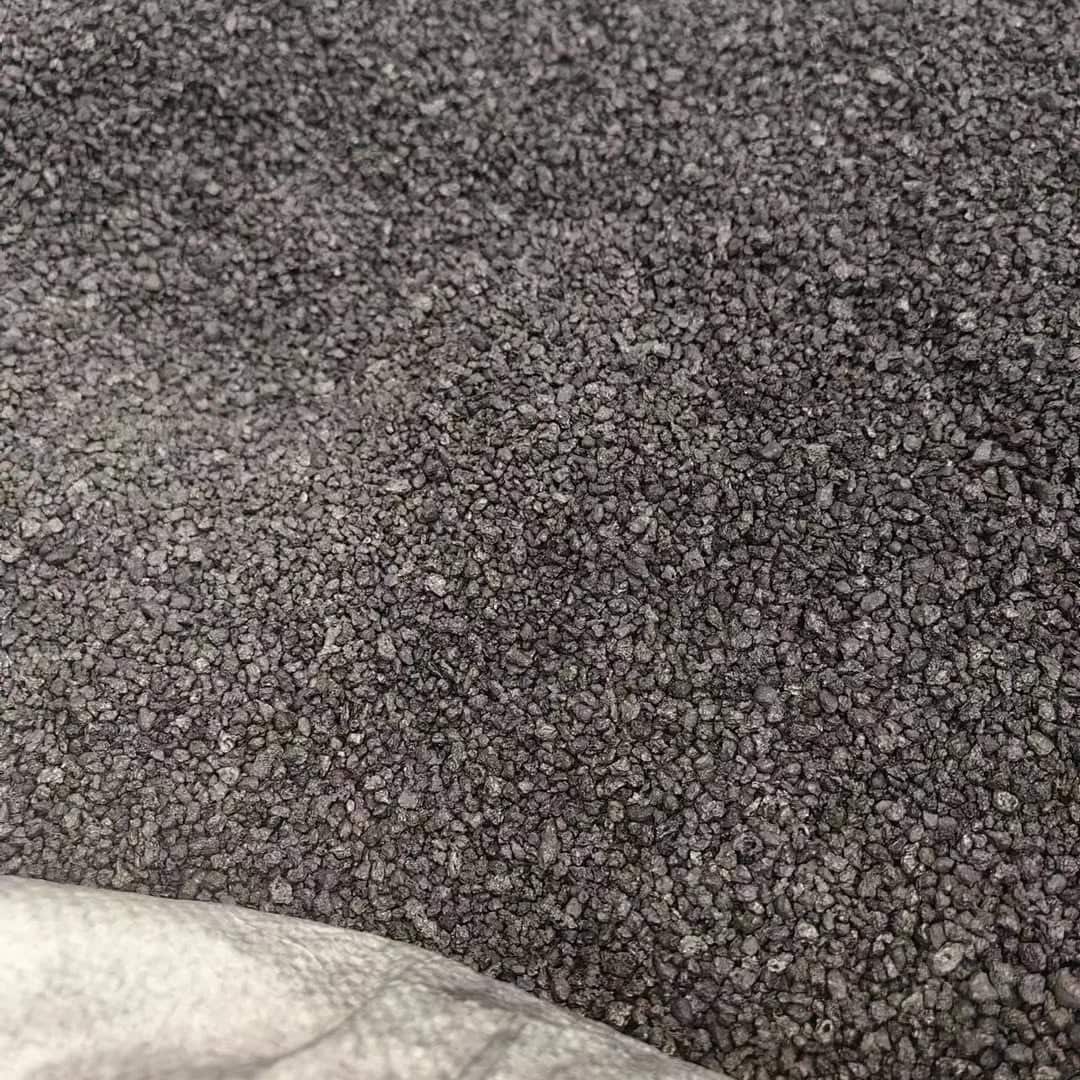

Professional Summary – Graphitized Petroleum Coke (GPC)

Graphitized Petroleum Coke (GPC) is a high‑purity carbon material produced by subjecting selected petroleum coke to ultra‑high‑temperature graphitization, typically in the range of 2,500–3,500 °C

This process transforms the carbon structure into a highly ordered graphite lattice, significantly improving purity, electrical conductivity, and thermal stability

The material is characterized by very high fixed carbon content (up to 99.7%), low sulfur, low ash, low volatile matter, and controlled particle size distribution, making it a premium solution for carbon‑critical metallurgical and industrial applications

Based on the provided Certificate of Analysis, the referenced GPC grade exhibits

Fixed Carbon: ≈ 99.25%🔹

Sulfur (S): ≈ 0.03%🔹

Ash: ≈ 0.35%🔹

Volatile Matter (VM): ≈ 0.40%🔹

Moisture: ≈ 0.41%🔹

Particle Size: 1–5 mm🔹

These parameters place the material firmly within the high‑purity, low‑impurity category, suitable for applications where strict control of residual elements is required

GPC is widely used as a carbon raiser (recarburizer) in steelmaking, cast iron, and alloy production, where precise carbon adjustment and low sulfur input are essential. Compared to alternatives such as anthracite or non‑graphitized petroleum coke, GPC offers faster dissolution kinetics, more predictable carbon recovery, and lower contamination risk, especially in high‑quality steel grades and ductile iron production

Beyond metallurgy, graphitized petroleum coke is also applied in graphite electrodes, battery anode materials, carbon composites, friction materials, and as an additive in plastic and rubber compounds, where its graphite‑like structure enhances conductivity, strength, and thermal performance

Due to its energy‑intensive production process, GPC is typically selected for applications where performance, consistency, and purity justify its premium positioning in the supply chain. It is particularly relevant for industrial markets across Eurasia, Europe, and Asia, where demand for high‑quality steel, advanced foundry products, and energy‑related materials continues to expand

| Parameter | Test Method | Unit | Result |

|---|---|---|---|

| Fixed Carbon Content | Copper sulfate colorimetric method | % | 99.25 |

| Moisture Content (H₂O) | Oven drying method | % | 0.41 |

| Sulfur Content (S) | Copper sulfate colorimetric method | % | 0.03 |

| Ash Content | Furnace / Drying method | % | 0.35 |

| Volatile Matter (VM) | Oven drying method | % | 0.40 |

| Nitrogen (N) | Elemental Analysis | % | 0.03 |

| Particle Size Distribution | Screening | mm | 1–5 |

?What Is Graphitized Petroleum Coke (GPC)

Graphitized Petroleum Coke (GPC) is a high‑carbon material produced by graphitizing calcined petroleum coke at very high temperatures

The process increases carbon purity and crystalline order, resulting in a material with high fixed carbon and low sulfur and ash, widely used as a controlled carbon additive in steelmaking and foundry operations

:Production and Graphitization Process

Graphitized Petroleum Coke is produced by subjecting calcined petroleum coke to high‑temperature graphitization, typically above 2,500 °C, in electric resistance or induction furnaces

During this process, volatile matter and residual impurities are reduced, and the carbon structure is reordered into a more crystalline, graphite‑like form, resulting in improved purity and metallurgical performance

:Key Technical Properties of GPC

Graphitized Petroleum Coke is characterized by very high fixed carbon content, low sulfur and ash levels, and a stable crystalline carbon structure

These properties result in predictable carbon dissolution, high carbon recovery, and minimal introduction of unwanted impurities during metallurgical processing

:2026 Price Outlook – Graphitized Petroleum Coke (GPC)

| Specification | Grade A | Grade B | Grade C |

|---|---|---|---|

| Fixed Carbon (%) | ≥ 98.5 | ≥ 98.0 | ≥ 97.5 |

| Sulfur (%) | ≤ 0.03 | ≤ 0.05 | ≤ 0.07 |

| Ash (%) | ≤ 1.0 | ≤ 1.5 | ≤ 2.0 |

| Volatile Matter (%) | ≤ 1.0 | ≤ 1.2 | ≤ 1.5 |

| Moisture (%) | ≤ 0.5 | ≤ 0.5 | ≤ 0.5 |

| Particle Size | 1–5 mm / 3–8 mm | 1–5 mm / 3–8 mm | 1–5 mm |

| Packing | 1 MT Big Bag | 1 MT Big Bag | 1 MT Big Bag |

| Price Range (USD/MT) | 440–520 | 400–460 | 350–400 |

| Delivery Term | FOB / CFR / CIF | FOB / CFR / CIF | FOB / CFR / CIF |

| Origin | Iran / China | Iran / China | Iran |

Prices are indicative and subject to change based on quantity, packaging, origin, and shipping route

:Typical Chemical Analysis (COA Reference)

A typical COA for Graphitized Petroleum Coke shows fixed carbon levels above 99%, with low sulfur and ash contents

Such chemical stability allows precise control of carbon input while minimizing the introduction of unwanted elements into the melt. Reported values may vary slightly depending on raw material quality and graphitization conditions

:Industrial Applications of GPC

Graphitized Petroleum Coke is widely used across metallurgical and carbon‑based industries. Its primary applications include carbon supplementation in steelmaking, inoculation and recarburization in foundry operations, and selected uses in electrode, friction, and battery‑related materials where high carbon purity is required

:GPC as a Carbon Raiser in Steel and Foundry

In steel and cast iron production, GPC functions as a high‑efficiency carbon raiser, offering consistent dissolution behavior and high carbon recovery

Low sulfur and ash levels make it suitable for applications where chemical cleanliness and tight carbon control are critical, particularly in quality steel and ductile iron grades

:Frequently Asked Questions

?What is Graphitized Petroleum Coke (GPC) used for

GPC is mainly used as a carbon raiser in steelmaking and foundry processes, where high carbon purity and low sulfur content are required for precise metallurgical control

?How is GPC different from calcined petroleum coke (CPC)

GPC undergoes an additional high‑temperature graphitization step, resulting in higher carbon crystallinity, lower impurity levels, and more stable dissolution behavior compared to CPC

?Why is low sulfur important in GPC

Low sulfur minimizes sulfur pickup in molten metal, which is critical for maintaining mechanical properties and meeting specification limits in quality steel and ductile iron production

?What particle size of GPC is commonly used

Common metallurgical sizes range from 1–5 mm, balancing dissolution speed and process control. The optimal size depends on furnace type and addition practice

?Does GPC fully dissolve in molten steel or iron

GPC shows high carbon recovery under proper process conditions, though actual recovery depends on temperature, residence time, and addition point

?Is GPC suitable for both steel and foundry applications

Yes. GPC is used in both steelmaking and cast iron operations, particularly where tight carbon control and low impurity levels are required

:Conclusion

Graphitized Petroleum Coke (GPC) is a high‑purity carbon material produced through high‑temperature graphitization, offering high fixed carbon content and low impurity levels

Its stable chemical composition and controlled particle size enable predictable carbon dissolution and efficient carbon recovery in metallurgical processes

Typical COA values confirm GPC as a suitable carbon raiser for steelmaking and foundry applications, where precise carbon control and low sulfur input are essential

When properly selected based on specification and size distribution, GPC supports consistent process performance without introducing unwanted elements into the molten metal

Phone: +989121684359

WhatsApp: +989121684359

For more information, visit our website: Ferrosilicon.co 🌐