Summary: Graphite Petroleum Coke (GPC)

is a premium carbon material engineered for steelmaking, foundry, and metallurgical applications, offering high fixed carbon, low sulfur, and controlled ash levels

Sourced and supplied through established Eurasian logistics corridors, this grade ensures consistent quality, stable supply, and competitive export pricing for international industrial buyers

Designed to meet the technical requirements of EAF steel mills, induction furnaces, and carbon raiser applications, High Quality Eurasia GPC supports improved metallurgical performance, lower melt loss, and predictable carbon recovery

Supply is optimized for Europe, Eurasia, Middle East, and Asian industrial markets, with flexible bulk and big bag loading options

This product is part of a global ferroalloy & carbon materials supply network, managed in coordination with

FERROSILICON.CO – Global Ferroalloy & Carbon Materials Export Platform

🔗Graphite Petroleum Coke – Overview | Eurasian Producer

Through integrated sourcing, export logistics, and market-specific specification control, this Eurasian-grade Graphite Petroleum Coke delivers reliability, scalability, and long-term supply confidence for professional buyers

| Feature (Property) | Test Method (Standard) | Unit | Test Result |

|---|---|---|---|

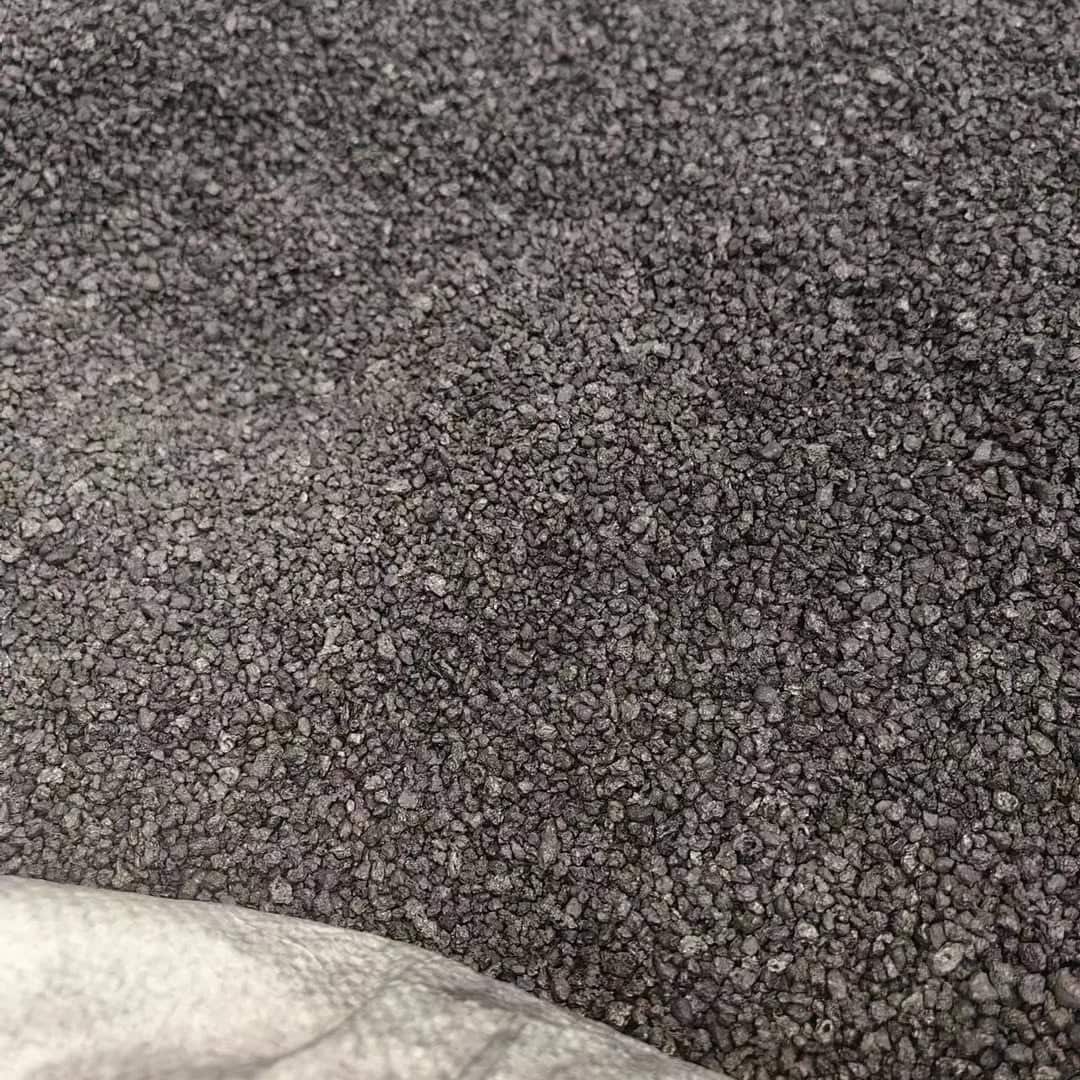

| Appearance | — (This product should be black solid) | — | Complies |

| Carbon Content (Fixed Carbon) | Copper sulfate colorimetric method | % | 99.25 |

| Moisture Content | Oven drying method | % | 0.41 |

| Sulfur Content | Copper sulfate colorimetric method | % | 0.03 |

| Ash Content | Oven drying method | % | 0.35 |

| Volatile Matter | Oven drying method | % | 0.40 |

| Nitrogen | Elemental Analysis | % | 0.03 |

| Granularity | Screening | mm | 1–5 |

:Technical Specifications & Certificate of Analysis

This Graphitized Petroleum Coke (Artificial Graphite Fines) is supplied based on batch‑verified laboratory analysis, ensuring consistent chemical purity and predictable metallurgical performance. The following technical parameters represent actual measured values under controlled testing conditions, not nominal or marketing ranges

Chemical Composition (Typical Analysis)

The material exhibits exceptionally high fixed carbon content (99.25%) with ultra‑low sulfur (0.03%), making it suitable for critical steelmaking and foundry applications where impurity control is essential

Carbon and sulfur levels are determined using the copper sulfate colorimetric method, while moisture, ash, and volatile matter are measured via standard oven drying procedures. Nitrogen content is verified through elemental analysis to confirm low gaseous impurity risk during melting

Physical Characteristics

The product is supplied as a black, solid granular material with a controlled particle size range of 1–5 mm, optimized for

Rapid carbon dissolution✅

Stable carbon recovery✅

Minimal dust generation during handling✅

Granulometry is verified by mechanical screening to ensure uniformity across shipments

Quality & Process Control

Each shipment is accompanied by a Certificate of Analysis (COA) issued for the specific production batch. The COA confirms

Compliance with declared chemical limits✅

Process stability across key parameters (C, S, Ash, VM)✅

Traceability for quality assurance and commercial documentation✅

This approach minimizes performance variability compared to generic petroleum coke grades and supports predictable melt behavior in EAF and foundry operations

:Graphite Petroleum Coke for Metallurgical Applications

Graphite Petroleum Coke (GPC) is a high‑purity carbon material used as a recarburizer in steelmaking and foundry operations

Produced through high‑temperature graphitization, it offers high fixed carbon, low sulfur, and stable dissolution behavior, supporting precise carbon control in electric arc and induction furnaces where chemistry consistency is critical

:Price Overview – Graphite Petroleum Coke (2026)

The price of Graphitized Petroleum Coke (GPC) in 2026 is influenced by a combination of carbon purity, sulfur control, particle size, and batch‑level quality consistency. Unlike commodity petroleum coke, GPC pricing reflects its role as a process‑critical metallurgical input rather than a bulk fuel or filler material

Market prices are typically quoted on an FOB or CFR basis, depending on volume, packaging format, and destination. Final pricing is subject to confirmation based on order size, quality requirements, and commercial terms

| Product Grade | Carbon (%) | Sulfur (%) | Particle Size | Packaging | Indicative Price Range (USD/MT) |

|---|---|---|---|---|---|

| GPC – Standard Metallurgical | ≥99.0 | ≤0.05 | 1–5 mm | Big Bag / Bulk | 480 – 560 |

| GPC – Low Sulfur Grade | ≥99.2 | ≤0.04 | 1–5 mm | Big Bag / Bulk | 520 – 620 |

| GPC – Premium Carbon Control | ≥99.25 | ≤0.03 | 1–5 mm | Big Bag / Bulk | 580 – 720 |

| GPC – Small Lot / Trial Supply | ≥99.0 | ≤0.05 | 1–5 mm | Bags | On Request |

| Product Grade | Carbon (%) | Sulfur (%) | Particle Size | Packaging | Indicative Price Range (USD/MT) |

| GPC – Standard Metallurgical | ≥99.0 | ≤0.05 | 1–5 mm | Big Bag / Bulk | 480 – 560 |

| GPC – Low Sulfur Grade | ≥99.2 | ≤0.04 | 1–5 mm | Big Bag / Bulk | 520 – 620 |

| GPC – Premium Carbon Control | ≥99.25 | ≤0.03 | 1–5 mm | Big Bag / Bulk | 580 – 720 |

| GPC – Small Lot / Trial Supply | ≥99.0 | ≤0.05 | 1–5 mm | Bags | On Request |

:Quality Indicators: Fixed Carbon, Sulfur, Ash & Impurity Control

The performance of Graphite Petroleum Coke in metallurgical operations is defined primarily by its fixed carbon content and the degree of impurity control achieved during processing

High fixed carbon supports efficient carbon recovery, while low sulfur levels reduce the risk of sulfur pickup in molten steel and cast iron, a critical requirement for quality‑sensitive grades

Ash content directly influences slag formation and furnace efficiency; lower ash minimizes unwanted slag volume and improves process stability

Controlled levels of trace impurities further contribute to predictable melt behavior, making the material suitable for applications where tight chemical tolerances and repeatable results are essential

:Typical Industrial Applications & Use‑Cases

Graphite Petroleum Coke is widely used across metallurgical sectors as a recarburizing material where consistent carbon adjustment is required. Typical applications include

Steelmaking: Carbon correction in EAF and induction furnaces with emphasis on low sulfur input

Foundries: Carbon adjustment in gray and ductile iron production

Recarburization: Precise carbon recovery in liquid metal without introducing excess impurities

Premium Cast Iron: Production of high‑quality cast iron grades requiring stable chemistry and controlled microstructure

Selection and dosing are optimized based on furnace type, charge composition, and desired metallurgical outcomes.

:Granularity, Handling & Storage Guidelines

Graphitized Petroleum Coke is supplied in controlled granular form, optimized for metallurgical handling and predictable dissolution

Particle size distribution is selected to balance carbon recovery efficiency with safe bulk handling

Typical Particle Size Parameters

| Parameter | Typical Value |

|---|---|

| Granulometry Range | 1–5 mm |

| Median Particle Size (d50) | ~3 mm |

| Form | Solid granular |

| Dust Level | Low (mechanically screened) |

| Parameter | Typical Value |

| Granulometry Range | 1–5 mm |

| Median Particle Size (d50) | ~3 mm |

| Form | Solid granular |

| Dust Level | Low (mechanically screened) |

Handling & Storage Considerations

Material should be stored in dry, covered conditions to prevent moisture absorption

Direct exposure to rain or high humidity may affect dosing accuracy✅

Standard bulk or bag handling equipment is suitable due to stable mechanical properties✅

No special storage requirements beyond common carbon material practices✅

Moisture management is recommended primarily for process consistency, not safety risk

:Available Markets & Geographic Supply Coverage

This product is commercially positioned for Eurasian‑centric supply, with flexibility to serve international metallurgical markets based on contractual and regulatory conditions

Typical Market Coverage

| Region | Market Status |

|---|---|

| Eurasia | Core supply region |

| Middle East | Active industrial markets |

| Asia | Select steel and foundry applications |

| Europe | Subject to product qualification and compliance |

| Global Specialty Markets | Case‑by‑case |

:Packaging, Loading & Bulk Supply Options

The product is available in multiple standard industrial packaging formats to accommodate different receiving and handling systems at customer facilities

Standard Packaging Options

| Packaging Type | Typical Use Case |

|---|---|

| 25 kg Bags | Laboratory trials, small batch use |

| Big Bags (≈1 MT) | Foundries, medium‑scale steel operations |

| Bulk | Large‑volume industrial consumers |

Packaging selection is determined by buyer preference, unloading infrastructure, and internal material handling practices. No specialized loading requirements are imposed beyond standard carbon material protocols

:Frequently Asked Questions

?What is Graphite Petroleum Coke used for in metallurgy

Graphitized Petroleum Coke is primarily used as a recarburizer in steelmaking and foundry operations. It provides controlled carbon input with low sulfur and ash, supporting precise chemistry adjustment in electric arc and induction furnaces

?How does Graphitized Petroleum differ from regular petroleum coke

Unlike conventional petroleum coke, Graphite Petroleum Coke undergoes high‑temperature treatment that increases carbon purity, improves crystalline structure, and significantly reduces sulfur and volatile matter, resulting in more stable metallurgical performance

?Why is low sulfur content important in recarburizers

Low sulfur limits the risk of sulfur pickup in molten metal, which is critical for producing quality steel and premium cast iron grades where chemical specifications and mechanical properties must be tightly controlled

?What particle size is typically supplied

The material is typically supplied in the 1–5 mm granular range, with a median particle size (d50) around 3 mm, optimized for efficient dissolution and practical furnace handling

?Does the material require special storage conditions

No special storage conditions are required. Standard dry, covered storage is recommended to avoid moisture absorption and to maintain consistent dosing accuracy during use

?Is a Certificate of Analysis (COA) provided

Yes. Each shipment is accompanied by a batch‑specific Certificate of Analysis (COA) reporting measured values for key parameters such as carbon, sulfur, ash, and volatile matter

?Is MSDS documentation available

A Material Safety Data Sheet (MSDS) is provided when available or upon request, in line with standard commercial and industrial documentation practices

?In which regions is this product typically supplied

The product is commercially available across Eurasia, with selective supply to the Middle East, Asia, Europe, and global specialty markets, subject to regulatory and contractual conditions

:Conclusion

Graphite Petroleum Coke is a high‑purity, metallurgical‑grade carbon material designed for applications where precise carbon control, low sulfur input, and process consistency are essential

Its controlled granulometry, verified chemical composition, and batch‑specific documentation make it a reliable choice for steelmakers and foundries seeking predictable recarburization performance without introducing unnecessary impurities

By aligning material quality, industrial applications, and transparent certification practices, this product supports stable production outcomes across steelmaking and premium cast iron operations, subject to proper technical evaluation under actual furnace conditions

specification‑driven understanding of GPC in an evolving international market

Phone: +989121684359

WhatsApp: +989121684359

For more information, visit our website: Ferrosilicon.co 🌐